The processing of diverse kinds of biomass using ionic liquids has been developing fast within the last decade, and today a significant number of scientific papers are published and patents are applied per year globally. Why then didn’t ionic liquids break through commercially yet?22.08.2023

The processing of diverse kinds of biomass using ionic liquids has been developing fast within the last decade, and today a significant number of scientific papers are published and patents are applied per year globally. E.g. the deconstruction of lignocellulosic biomass by pretreatment with ionic liquids has been unmet by other technologies since more than 15 years, in terms of robustness, feedstock variability and sugar yield. Why then didn’t ionic liquids break through commercially yet?

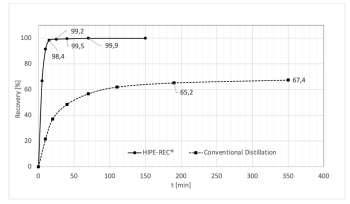

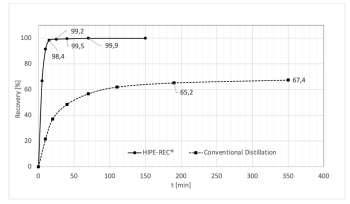

One of the signature properties of ionic liquids is their extremely low vapor pressure, which makes an evaporative workup impossible. In order to recover the valuable ionic liquid after processing of biomass, it has to be washed with huge amounts of water, and the water has to be evaporated subsequently, consuming a lot of energy. In most cases, the recovered ionic liquid is contaminated with water soluble biomass residues and needs further purification steps, incorporating costly and sensitive technologies, such as membrane-based ones. A special class of ionic liquids are distillable ionic liquids, which do have a significant vapor pressure; however, the evaporation characteristics are not comparable to classical molecular solvents and removing them from a highly viscous biomass slurry by conventional distillation techniques fails to meet the mandatory efficiencies of > 99% by far, typically reaching values of not more than 80-90% at max.

proionic GmbH has now fundamentally solved this problem and announces the "HIPE-REC®" technology ("High Performance Recovery" - patent pending WO2023084131): This new technology combines the feedstock and process specific selection of special distillable ionic liquids with the application of a thin-film high viscosity evaporation technology, which is established in other industries since decades, as for instance in the polymer industry. The high-viscosity evaporator device continuously renews a large evaporation surface in the biomass-ionic liquid-mixture and is capable to handle even viscosities up to several 1000 Pas.

© GIGKarasek, a partner of proionic GmbH

The ionic liquid is now easily distilled of at nearly quantitative recovery rates under mild conditions, typically needs no further purifications steps and is ready for the next cycle. The resulting ionic-liquid processed biomass is ready to use for any follow up process step directly, preventing the need for huge amounts of washing water, and saving energy and time.

Fig.1: Recovery of distillable ionic liquid Ethanolammonium-acetate (Tb = 210 °C at 1 atm) from pretreated sorghum bicolor at 1 mbar and 140 °C, using conventional technology versus proionic’s HIPE-REC® (WO2023084131) technology.

Send us an email.

Share your ideas with us! Do you have an application where distillable ILs could be the key to the solution?

office@proionic.com